Hydrolysis resistant nylon material to play a new pattern

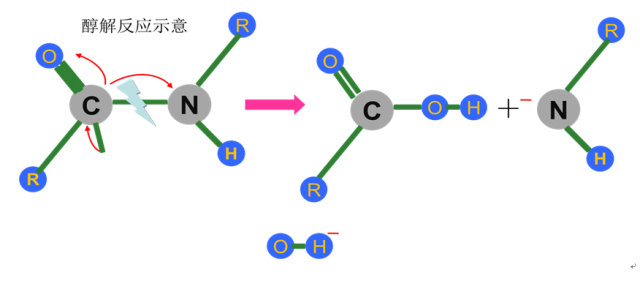

Nylon is easy to form hydrogen bonds with water molecules because it contains amine groups and carbonyl groups. Therefore, various materials obtained are easy to absorb water when in use. The most commonly used PA6 and PA66 can absorb up to 10% of the water by mass from humid air, and can also absorb 2% to 4% of the water by mass in normal humidity environment. Under the action of heat, hydroxyl groups attack amide bond carbonyl groups, its amide bond is broken to form a carboxylic acid and "hydrolysis", resulting in a variety of mechanical properties changes.

Polyamide Hydrolysis and Alcoholysis

How to realize the "hydrolysis resistance" of nylon, R & D workers from the "table" and "in" put forward their own three-step solution.

Hydrolysis resistant scheme "three steps":

Step 1 "Defense" heat-resistant surface protection technology

At a certain temperature, a certain number of-OH groups and small molecular groups that can initiate hydrolysis reaction are free from water, and react with the polyamide groups on the surface of the material. With the deepening of the reaction, the internal bond of the molecular chain is broken, and hydrolysis occurs, which eventually makes the performance of the material greatly damaged.

"Defense" technology is the use of additives and alloying technology, so that in the injection molding process in the surface of the parts to form a layer of hydrophobic "interlayer", under the action of heat to generate a layer of dense inert carbon layer, through this "shield" effect, can be isolated from the vast majority of oxygen and hydrolysis molecules, to prevent its further erosion of the internal molecules, effectively protect the internal molecular structure

Step 2 Internal Control Technology of Sub-chain

Inside the nylon molecule, the end of the molecular chain and the free small molecules are the most easily reacted parts. How to unite these weakest "small partners" is also crucial to the final hydrolysis resistance of the material. Through the molecular crosslinking technology, a more rigorous molecular chain network structure is formed on the molecular surface, which further increases the difficulty of combining the hydrolysis group with the carbonyl group, prevents the molecular chain from breaking and inhibits the hydrolysis of the polyamide.

Step 3 Glass Fiber Compatibility Technology

Glass fiber can significantly improve the mechanical strength of nylon materials, and the combination between them will directly affect the mechanical strength and hydrolysis resistance of the final material. Under the action of thermal hydrolysis, the bonding force between glass fiber and resin interface is the weakest place, and it is also the most vulnerable to be "attacked". "Compatibility technology" means that "nylon/glass fiber" is changed into "nylon-G-glass fiber" through a "G" which has good binding force with polyamide and glass fiber. Through the bridge effect of "G", the binding force between glass fiber and nylon resin is stronger, and the hydrolysis of hydroxyl group requires greater bond energy, thus improving the hydrolysis resistance effect of the material.

Hydrolysis resistant nylon application case

car radiator

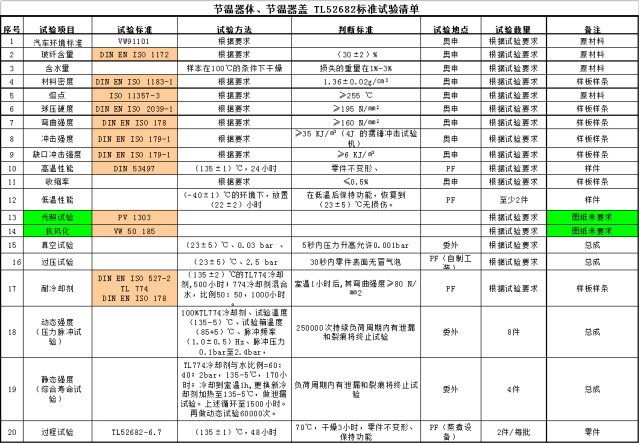

The original car radiator is made of metal. With the development of technology, hydrolysis-resistant materials with good performance can gradually replace metals. In the industry, there are relevant standards for nylon materials for automobile radiators. Among them, the Volkswagen thermostat parts standard TL52682 is one of the most stringent standards. The hydrolysis-resistant material A6G7406 has been successfully applied to automobile heat dissipation water chamber thermostat parts. Passed the Volkswagen thermostat parts standard.

A6G7406 Pass TL52682 Standard Test List

A6G7406 for VW thermostat

Cleaning areas

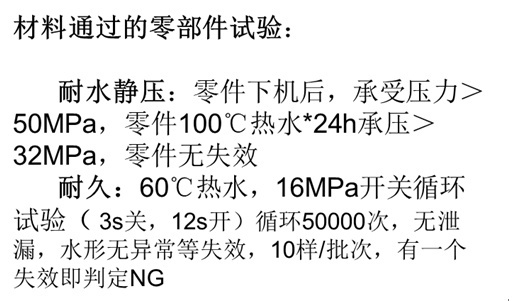

In addition to the successful application of the car water chamber, the hydrolysis resistant nylon material also performs well in the cleaning equipment. In order to ensure good cleaning effect, the cleaning machine needs extremely high static pressure, and some high-end models even require more than 25MPa, which requires the material to have higher hydrolysis strength and quality stability. The cleaning equipment produced by the use of the rising blasting pressure hydrolysis resistant nylon A9G74 products has been successfully exported to Europe and the United States and other international markets.

Life Bathroom

Kitchen and bathroom equipment is another one of the most common application areas in the field of water contact. Brass has excellent performance but is expensive. Hydrolysis resistant nylon "ATXG74" series, on the basis of hydrolysis resistance, has better dimensional stability and good resistance to long-term environmental aging system. Hydrolysis resistant nylon has the ability to become one of the best replacement materials for the upgrading of bathroom equipment in the future.

Water Heater

Three-way valve

Faucet valve

That's all for today's introduction. If you are interested in these materials we are talking about, you can directly contact us "021-64909700". In the next lecture, we will introduce "the second of the" water-resistant "materials used in environmental protection machinery-acid and alkali-resistant materials". The water here is dirtier. How does the material perform? Look forward to it.