The reshuffle of the plug-in industry has begun | under the enforcement of the new national standard, have you got to the point?

Since April 14, the new national standard for plug-in has been enforced, and the plug-in industry is about to face a major reshuffle. As a plug-in manufacturer, do you know the strict requirements of the new national standard for plug-in safety, and can you still stay on the card table after this round of reshuffle?

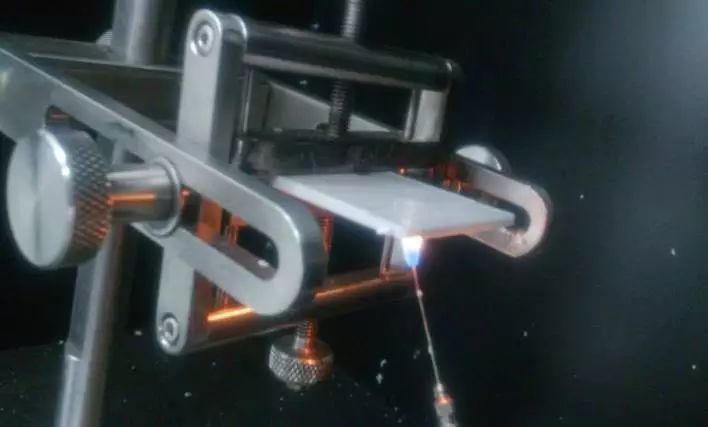

Although the new national standard has been enforced, many plug-in manufacturers still do not know much about the new national standard, especially the flame retardant needle flame test, and even some third-party testing institutions do not know the relevant testing rules in the needle flame test, thus causing the test results to deviate from the actual problem. Let's understand the key points of this round of reshuffle (new national standard) with Xiaobian: plug safety test-needle flame test.

According to the different test samples, the test is divided into two cases:

1

Integral components

Article 6 of GB/T5169.5-2008 specifies that the test sample shall be a complete equipment, assembly, or part, unless it is necessary to remove part of the test.

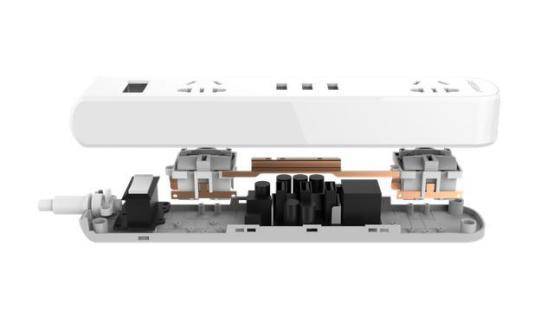

The second test position focuses on the part that needs to fix the current-carrying parts, and the new national standard requires it to reach 750 ℃ (for example, the lower half of the shell of the fixed current-carrying copper part in the figure below)

Ⅲ Test environment. During the test, if the glow wire test flame exceeds 2S, the needle flame test specified in the appendix shall be carried out. The needle flame test point should be at least 10mm away from the corner of the test sample.

2

Intercepting or direct injection molding sample testing

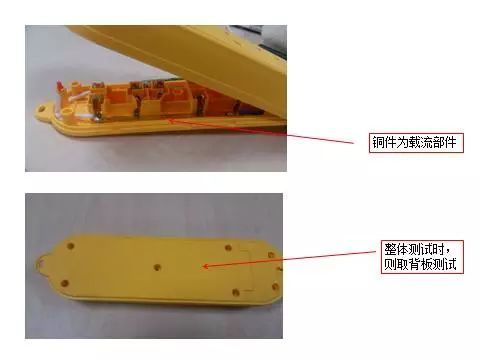

I sample When the whole product is not suitable for testing (the product structure is complex), intercept the product part or injection sample test.

II test position interception or sample test edge, as shown in the figure below. According to GB/T 5169.5-2008-Part 5: Test Flame Needle Flame Test Method Device, Confirmation Test Method and Guidance ≥ Item 6, the test can be intercepted if necessary, but care must be taken to ensure that the flame is not applied to the edge produced by cutting by mistake.

Ⅲ During the test environment test, if the glow wire test flame exceeds 2S, the needle flame test specified in the appendix shall be carried out. The needle flame test point should be at least 10mm away from the corner of the test sample.

Having said so many precautions, have you got to the point of the needle flame test? Let's go through the train of thought again:

1)750 ℃ glow wire test, the flame exceeds 2S before the needle flame test is required.

2) Try to use the whole piece, not the partial piece.

3) When the whole piece is used, the test position is selected to connect the plastic parts of the conductor.

4) Regardless of whether the whole piece or the partial piece, the flame height should not exceed 12mm, and the concentrated point of the flame should be more than 10mm away from the edge.

Finally, I have finished the needle flame test. I believe everyone understands the specialty and complexity of the needle flame test. It is no wonder why many plug-in manufacturers and even third-party testing organizations are not clear. In fact, to ensure the safe use of plug-in, it is not enough to make clear the test experiment. The key is to choose the right safe and suitable plastic.

Bull, Legrand and other first-line plug-in brands have long been looking for suitable electrical safety plastics and have been put into use before the implementation of the new national standard. Plastic Yi'an is the most suitable electrical safety plastic they have found.

The special electrical safety plastic for plastic plug-in has the national 3C certification and meets all the requirements of the new national standard for plug-in shell materials. It is the first choice for almost all first-line brands at present.

modified engineering plastics

微信ID:ME-plastic

Modified engineering plastics micro forum avatar. png modified engineering plastics micro forum avatar. png

1. Click on historical information to see more content

2. Press the two-dimensional code on the right and pay attention to WeChat public forum.