Weather-resistant halogen-free flame retardant polypropylene material-safety guard for outdoor seats

A large number of plastic seats in stadiums, meeting places, leisure places, stations, airports, hospitals have become an integral part of modern life. These plastic seats are usually made of blow-molded PP, HDPE or injection-molded co-polymer PP. Under outdoor conditions, the molecular chain is prone to fracture, and light stabilizers need to be added to improve its weather resistance. In addition, these public places are crowded, and the flammability of seats has serious potential safety hazards, so flame retardant modification of materials is required.

In the material weather resistance and flame retardant modification, need to pay attention to the following issues:

1, light stabilizer is generally hindered amine light stabilizer, flame retardant can be divided into halogen flame retardant and halogen-free flame retardant, halogen flame retardant efficiency is generally better than halogen-free flame retardant, but halogen flame retardant combustion will take a lot of toxic smoke.

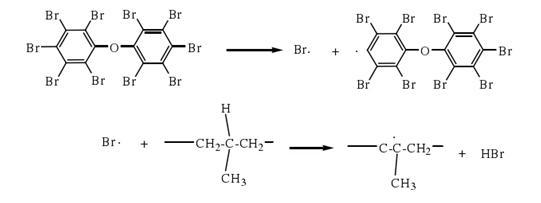

2, halogen flame retardants will accelerate the speed of polyolefin light aging. Taking the bromine flame retardant polypropylene as an example (Figure 1.1), the bromine radical generated under light captures the tertiary hydrogen on the molecular chain and accelerates the light decomposition of PP. In addition, the generated HBr will react with alkaline hindered amines, resulting in the failure of the light stabilizer.

Figure 1.1 Effect of brominated flame retardants on photo-oxidative degradation mechanism of polypropylene

3. The compatibility between halogen-free flame retardant and polyolefin is poor, adding a large amount of flame retardant has a great influence on the mechanical properties of the material, and the surface is easy to precipitate.

In order to better optimize and balance the flame retardant, weather resistance and mechanical properties of the product, Rizhisheng has developed a weather-resistant halogen-free flame retardant polypropylene material, which is characterized:

1, the system added a high-efficiency halogen-free flame retardant, in the case of a small amount of addition to achieve the V-2 level of flame retardant requirements, which not only reduces the impact of flame retardant on the mechanical properties, but also weakens the flame retardant on the weather additives interference. The author compares the mechanical properties and flame retardancy of ordinary halogen-free polypropylene, high-efficiency halogen-free polypropylene and ordinary copolymer polypropylene. It can be seen from Table 1.1 that under the condition that the flame retardant performance also reaches V2, the tensile strength of high-efficiency halogen-free flame retardant polypropylene is increased by 20% and the notched impact strength is increased by 40% compared with ordinary halogen-free flame retardant polypropylene.

Table 1.1 Comparison of flame retardancy and mechanical properties of three kinds of polypropylene materials

2. Add light stabilizers with excellent weather resistance and compatibilizers tailored for the weather resistance-flame retardant system to ensure that the light stabilizers are fully dispersed with other components in the system, effectively absorb free radicals generated by light, and slow down the aging of polypropylene. According to the method experiment specified in the standard GB/T 16422.2-1999, there is no obvious change on the surface of the material under 1000h of light, which fully meets the weather resistance requirements of outdoor seats.