Realization of Laser Marking of Nylon Flame Retardant Reinforced Material

Laser marking, the product of this contemporary high-tech laser technology, effectively overcomes many defects of traditional printing technology. Because it solves the problem that the surface mark of the material is blurred and difficult to identify due to mechanical friction, chemical action, etc., it has obtained rapid development.

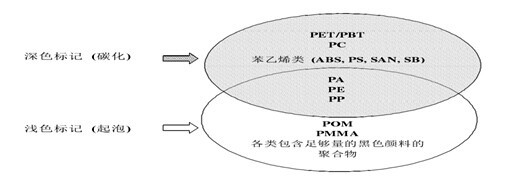

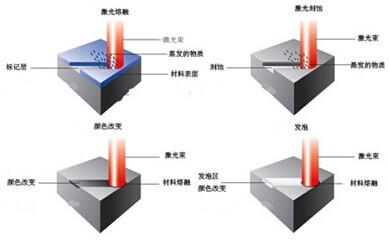

Laser marking mainly uses laser energy to produce marks on various materials. From metals and glass to ceramics and plastics, laser marking is available. For plastics, because of their different molecular structures, the principle of marking is also different. In general, it can be divided into two marking principles, carbonization (white or light products) and foaming (black or dark products).

It is important to note that materials such as polyamide (PA), polyoxymethylene (POM), and thermoplastic elastomers (TPE) cannot be laser-marked without physical modification. Such plastics must rely on laser additives to produce markings. Because nylon flame retardant materials are more difficult to achieve laser marking, and after flame retardant and fiber treatment, the factors affecting laser marking are more complex, only the role of various factors can achieve a clear and high contrast laser marking effect.

Based on the experience of experiment and production, this paper discusses the influence of each component of nylon flame retardant material on laser marking.

Influence of minerals on laser marking

Minerals such as talcum powder and kaolin are often added to flame retardant materials as synergistic agents. These minerals are easy to foam when laser marking, resulting in an increase in light reflection on the surface of the polymer. If it is a light-colored material, the effect of laser marking can be reduced.

Effect of Flame Retardant on Laser Marking

Whether it is halogen-containing or halogen-free flame retardants will have an impact on the marking effect of flame retardant products. Among them, aluminum hydroxide and aluminum hydroxide have a greater impact on laser marking, and the nitrogen-phosphorus system has a greater impact than the halogen system. Especially white or light-colored products.

Effect of Black Additives on Laser Marking of Nylon Flame Retardant Materials

Black flame retardant nylon product is one of the commonly used products, and carbon black, graphite, iron oxide and other additives have been proved to have a strong absorption of laser. The higher the content, the higher the heat absorption, resulting in high energy in the laser irradiated area, resulting in high polymer evaporation or decomposition, which may result in the formation of dents on the surface of the material and cannot form distinct marks.