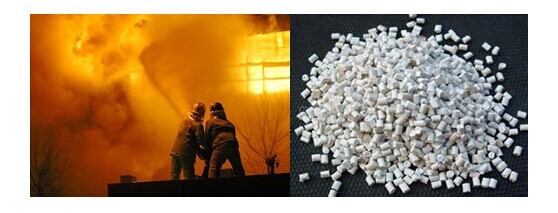

Red phosphorus flame retardant products can also be changed from red to white

Red phosphorus is a purplish red or slightly brown amorphous powder that can be used as an organic halogen-free flame retardant. It relies on the formation of phosphoric acid as a dehydrating agent and promotes charring, thereby reducing the heat conduction from the flame to the condensed phase and achieving high-efficiency flame retardant effect. The flame retardant products prepared by it have excellent thermal stability, non-volatility and excellent flame retardant performance, but there are the following problems in practical application:

Disadvantages: chemical properties are not stable, easy to absorb moisture in the air, easy to oxidize;

Disadvantage two: red phosphorus color dark red purple, generally can only be used for red and black products, the scope of application is greatly limited;

Disadvantage three: high temperature processing produces highly toxic gas phosphine PH3, dust explosion, there is a safety hazard in storage and transportation.

Solution: microencapsulation coating technology

The surface of red phosphorus was microencapsulated by a new type of microencapsulation coating technology. Selection of zinc borate ZB, melamine resin MF, ATH and other materials, a variety of organic and inorganic way of coating red phosphorus flame retardant, after surface treatment into the surface color of the white microcapsules is microencapsulated red phosphorus.

Advantage 1: effectively prevent moisture absorption and oxidation. Compared with uncoated red phosphorus, the thermal stability and chemical stability are significantly improved, and the performance indicators such as spontaneous combustion temperature, thermal decomposition temperature, water absorption, oxidation resistance and phosphine release are further improved. Widen the application of red phosphorus in high molecular polymer.

Advantage two: microencapsulated red phosphorus flame retardant due to the core-shell structure effect of microcapsules, in the process and use of non-red, high temperature resistance, can be appropriately used for light or white system. Add less weight, high flame retardant efficiency; small density, less impact on physical properties; can effectively prevent frosting, migration, corrosion mold phenomenon in the process of production and processing; in particular, the product has a high leakage trace index (CTI) under high temperature processing conditions.

Advantage 3: Although microencapsulated red phosphorus is coated, the ignition point generally reaches above 320 ℃, and the better coating can reach 800 ℃ or even 1000 ℃. It can reduce the risk coefficient of combustion and explosion of red phosphorus during use and avoid accidents.