Apple mobile phone spontaneous combustion triggered thinking-can use less or no flame retardant materials?

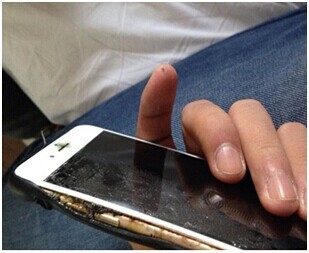

Recently, a domestic mobile phone user's iPhone6 has just started for 11 days, and there has been spontaneous combustion. At present, the specific cause of spontaneous combustion is not clear. Fortunately, the user found out in time and did not cause personal and property harm. Coincidentally, Apple immediately announced a brand new patent. The patent is mainly the application of a halogen-free flame retardant material. This material can improve the safety of electronic equipment and help reduce the cause of electronic equipment. The fire, and the halogen-free flame retardant material greatly reduces the release of harmful substances to the environment during combustion. After this patent is put into practice, the iPhone may no longer be afraid of spontaneous combustion. Even if the battery burns, the fire source can be limited to a certain space without causing too serious consequences.

I saw a lot of netizens have such a point of view "superfluous, the inside is burning, what is the use of wrapped with flame retardant material? It is not scrapped." So why is Apple risking the cost of using halogen-free flame-retardant materials? Is it just because of public pressure? Although some manufacturers of electronic and electrical products believe that people can design fault-free electrical components to prevent products from becoming a source of fire, so there is no need for flame-retardant housings. But no matter what component, there will always be one or more defects, and this is likely to cause a fire accident. Do not use flame retardant materials, can indeed reduce product prices, and make plastic recycling easy, easy to meet environmental requirements. But do not use flame retardant materials will certainly increase the fire risk of the product, once the fire, the flame is easy to spread, and the use of other technical means to ensure fire safety seems to be still in the discussion stage, people are far from reaching a consensus. The application of flame retardant materials is not to eliminate the source of fire, but more to prevent or delay the spread of flame. The most typical representative is nothing more than "Chinese-style" external thermal insulation wall materials. With the country's call for "energy saving and emission reduction", local governments and builders have used polystyrene foam, polyurethane foam, etc. Highly flammable materials, and in order to reduce costs, no flame retardant ingredients were added at all, resulting in the most famous 2008 CCTV fire and Shanghai's "1115" major fire and other tragedies.

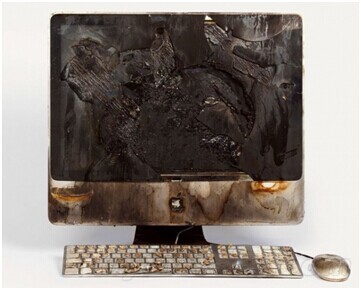

In the past 20 years, in Europe and the United States, a series of fire safety tests have been carried out on materials for electronic and electrical equipment (such as televisions and computers), and the results have proved that the use of appropriate levels of flame retardant materials to make electronic-Electrical equipment can greatly improve the level of fire safety. As early as 1987, the IEC60905 stipulated that flame retardant materials should be used for information processing equipment to minimize the risk of ignition and flame propagation of materials inside and outside the equipment. The regulation also details the circumstances under which fire-retardant materials are required for electrical and electronic equipment.

Reasonable material flame retardant is one of the strategic measures to reduce fire, and flame retardant and smoke suppression, attenuation can be achieved at the same time. The National Bureau of Standards (NBS) used small and large tests to compare the fire hazards of flame-retardant and non-flame-retardant samples of the following five typical plastic products:(1) polystyrene TV housings;(2) polyphenylene ether electronic computer housings:(3) polyurethane foam flexible chairs;(4) cables with polyethylene insulation and rubber sheath;(5) unsaturated polyester FRP circuit boards. The results of the test are as follows:(1) the time available for evacuating people and rescuing property after a fire, the flame retardant sample is 15 times that of the non-flame retardant sample;(2) the mass loss rate of the material during combustion, the flame retardant sample is less than 1/2 of the non-flame retardant sample;(3) the heat release rate of the material during combustion, the flame retardant sample is only 1/4 of the non-flame retardant sample;(4) The amount of toxic gas generated by material combustion (converted into CO meter) is only 1/3 of that of non-flame retardant sample. (5) Compared with the non-flame-retardant sample, the amount of smoke generated during combustion of the flame-retardant sample is lower.

Others believe that flame retardant materials release toxic substances to the environment when burned, and the use of flame retardant materials should be reduced. It is true that some halogen-containing flame retardant materials will release smoke when they burn. However, with the total ban on the use of polybrominated diphenyl ethers, polybrominated biphenyls and other halogen-containing flame retardants, the development and application of non-toxic halogen-containing flame retardant materials and halogen-free green environment-friendly flame retardant materials are also increasing. At present, they can be flame retardant and environmentally friendly, such as Apple's patent on halogen-free flame retardant materials mentioned at the beginning.

Material suppliers and additive suppliers should bear in mind that there is no market for materials and components that are not welcomed by customers, and products that are not considered for the vital interests and personal safety of customers are definitely not welcome. At the same time, product manufacturers sell products on the market, not materials, additives or components, so material suppliers should continue to meet product requirements for materials.