Flame Retardant Related Knowledge Phase I-Glow Wire Test

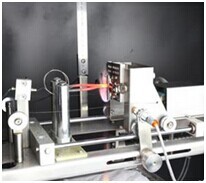

Glow wire test is to test the stability of electrical and electronic products at work. The glow wire itself is actually a fixed specification of the resistance wire ring, the test to use electric heating to the specified temperature, so that the top of the glow wire contact sample to reach the standard requirements of the time, and then observe and measure its state, the test range depends on the specific test procedure.

Test standard

Glow-wire flammability test method for finished products (IEC 60695-2-11:2000/ GB/T 5169.11-2006)

Glow-wire flammability test method for materials (IEC 60695-2-12:2000/ GB/T 5169.12-2006)

Test method for glow-wire ignition of materials (IEC 60695-2-13:2000/ GB/T 5169.13-2006)

Metrics Definition

1. Flammability index GWFI

GWFI——glow-wire flammability index

The maximum test temperature of a test sample of a specified thickness in three consecutive tests shall meet one of the following conditions:

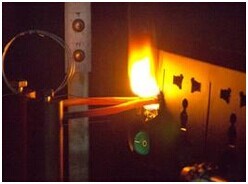

a) The flame or heat of the test sample is extinguished within 30 seconds after the glow wire is removed, and the packaging paper placed under the test sample does not ignite;

B) The test sample has no light-off.

Note: GWFI index is mainly to evaluate the self-extinguishing ability of materials.

2. Ignition temperature GWIT

GWIT——glow-wireignition temperature

25K (30K higher between 900 ℃ and 960 ℃) than the highest temperature at the top of the glow wire that does not cause the test sample of the specified thickness to ignite after three consecutive tests.

Note: GWIT index is mainly used to evaluate the flame retardant degree of materials.

Sample Requirements

1. The requirements of the SGS material laboratory for the test sample are: the sample sample should have a large enough flat part of fixed size, and the test plane should be kept in a vertical position during the test.

2. The test sample can be made in several ways: compression molding, injection molding or pouring, or cut from a finished part with a sufficiently large plane, such as a plate.

3. The size of the flat part should be: length: ≥ 60mm, width (inside the fixture): ≥ 60mm

4. The evaluation of flammability according to the requirements of this test usually requires a set of 10 test samples.

Evaluation of results

1. Glow Wire Flammability Index (GWFI)

Evaluation of results The test is considered to have survived the test if the test sample does not ignite or meets the following two conditions

a) If the flame or glow line of the test sample is extinguished within 30s after the glow wire is removed

B) No ignition of packaging paper

If either or both of the above conditions are not met, a lower test temperature is selected and the test is repeated with a new test specimen.

If the above two conditions are met at the same time, the test is repeated with a new test sample at a higher test temperature.

The test shall be repeated at the highest test temperature at which the test sample meets conditions a) and B).

It is determined that the GWFI is the highest test temperature that satisfies conditions a) and B) for three consecutive tests.

2. Glow-wire ignition temperature (GWIT) results of the evaluation

The light-off temperature of the test sample during the application of the glow-wire shall be determined and the test temperature 25K (30K between 900°C and 960°C) higher than the highest temperature at the top of the glow-wire that does not cause the test sample to light off for three consecutive tests shall be recorded as GWIT.