Make Electrical Products Safer-Material Selection

The development of the electronic and electrical industry represents the progress of national scientific and technological strength, ranging from space stations, space shuttles, automobiles, high-speed railways, to household appliances, building appliances, lighting appliances, etc. are closely related to the electronic and electrical industry. With the progress of society and the development of the times, electronic and electrical products have been more and more integrated into our daily life. It is electrical products and our lives so close to the disaster caused by electrical products are more and more people's attention and worry. Therefore, safe and reliable has become the primary factor for people to choose electronic and electrical products.

The design of the internal circuit, the protection of the operation interface, and the selection of electrical materials are all effective measures to improve the safety of electrical products. In this article, the author wants to talk about how to improve the safety and reliability of electrical products from the perspective of plastic material selection from his own professional point of view.

Electrical products use some plastic materials as a protective shell, these protective shell more or less and the internal resistance wire, line contact, often as the last barrier to protect the electrical itself. But this is the last level, once the control is not good, it will often lead to electrical failure, electric shock, fire and other serious consequences. The reason is that most of the shell materials are made of some ordinary flame retardant ABS,HIPS and other materials.

These traditional plastic materials often stay on the function of ordinary flame retardant. When it comes to flame retardant, people often confuse the concepts of flame retardant and non-combustible. In fact, flame retardant is only a relative concept, which only identifies the degree of flame retardant materials. Further, it actually evaluates the ability of the material to extinguish itself after leaving the fire environment. The higher the flame retardant level, the stronger the self-extinguishing ability of the material, and the less likely it is to spread the fire, which can delay the flame burning speed to a certain extent. But it does not represent the possibility of avoiding a fire. Electrical products produce fire, often there is no external flame, but due to short circuit or open circuit caused by the internal wire current is too large, the voltage is too strong, the wire in a short period of time to accumulate a large amount of heat, resulting in contact with the plastic material fire. Most of the fires in electrical products are due to this reason. Traditional flame retardant materials are difficult to withstand high current, high voltage environment to cause ignition. Therefore, it is necessary to upgrade the traditional flame retardant materials to improve the safety of electrical products.

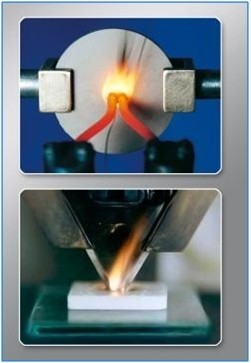

The new type of flame retardant plastic should not only have high flame retardancy, but also be able to withstand high current and high voltage environment. This is actually a new challenge to the research institutions and manufacturers of flame retardant materials. Researchers need to improve the safety of traditional flame retardant materials by adjusting the formula and improving the process while retaining the existing flame retardancy of the current flame retardant materials. At present, the International Electrotechnical Organization IEC has issued the corresponding evaluation means and safety level, which includes the glow wire temperature (GWIT) and the comparison of the leakage trace index (CTI). These two technical indicators are more important than UL94 flame retardancy. They respectively characterize the surface stability of plastic materials when they are in contact with high current and high voltage wires. Popular understanding, the material itself after the test of the glow wire temperature and compared to the higher the tracking index, the material in the actual high current, high voltage environment, the smaller the possibility of fire. Therefore, the selection of high GWIT and high CTI flame retardant materials for electrical products can truly achieve the purpose of fire prevention in unburned.

Many electrical manufacturers at home and abroad, such as Siemens, Haier, Schneider, etc., gradually incorporate GWIT and CTI into the technical evaluation system when selecting materials, which is very meaningful to improve the safety of electrical products. The development of flame retardant products with higher GWIT and higher CTI performance is not only the research and development hotspot of various modified plastic manufacturers and research institutions, but also will have a broader application market and will bring people's lives. Higher security assurance.