Material Selection-New Selection of Socket Shell Material PC/PBT

As a necessary device for daily connection of various electrical appliances, it integrates convenience, safety and practicality, which greatly facilitates people's daily life. With the improvement of people's living standards, the quality requirements of the row material is getting higher and higher, not only beautiful but also safe, long service life. This puts forward higher requirements and challenges to the material of the row housing.

ABS resin is currently the most commonly used plug-in shell material. ABS combines the properties of three polymers of PS,SAN and BS, has excellent mechanical properties of toughness, hardness and balance of rigid phase, and has good formability. The surface of the processed products is smooth and easy to dye and electroplate. Therefore, it can be used for household appliances, toys and other daily necessities. However, ABS itself has poor flame retardancy, with an oxygen index LOI of about 18%, which is a flammable plastic. Therefore, if the glow wire is inserted through the industry standard of 750 ℃, flame retardant treatment is required, which pushes up its price. ABS has poor heat resistance, and its use in high temperature environments will cause serious deformation. The lack of ABS in the above key indicators, resulting in ABS as a commonly used plug-in material, is gradually losing the favor of material manufacturers, and has been the continuous development of alloy materials and more cost-effective PP flame retardant materials instead.

The following author introduces an alloy material PC/PBT that is expected to replace ABS, taking into account the characteristics of the industry's requirements for plug-in materials. PC/PBT alloy materials combine the advantages of PC and PBT materials, with good flame retardancy, heat resistance and molding processability. However, due to the fact that both of them are prone to esterification reaction, the mechanical properties of PC/PBT alloy materials can be completely comparable to and beyond ABS materials with the development of technology and special technical inhibition measures.

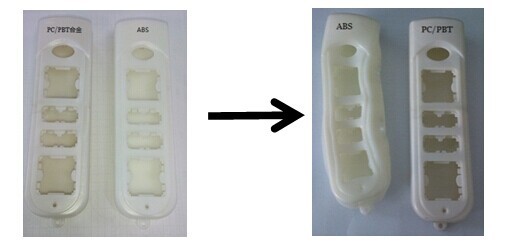

1. Good heat resistance and yellowing resistance

PC/PBT does not deform after baking at 100 ℃ for 1h, and ABS is seriously deformed.

ABS contains double bonds and is very unstable. Therefore, ABS is easy to be oxidized and yellow by heat and light, while PC/PBT alloy performs better.

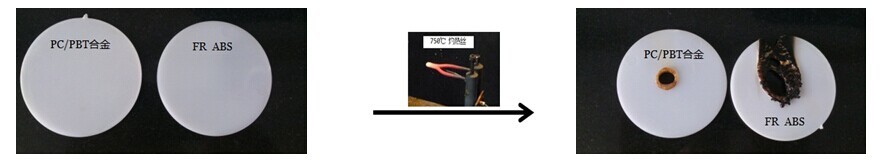

Glow wire does not ignite at 2.750 ℃

PC/PBT alloy and general flame retardant ABS after 750 ℃ glow wire contrast, PC/PBT does not ignite

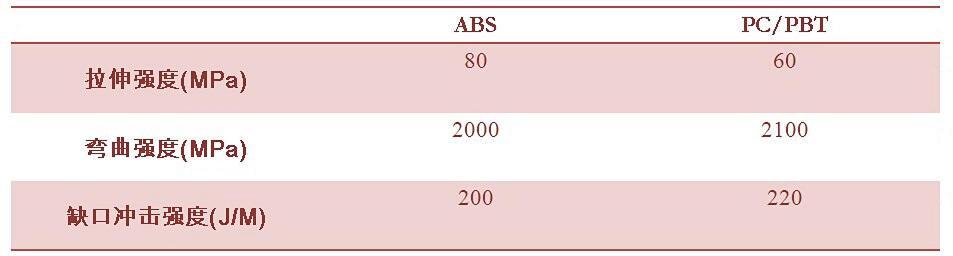

3. Good mechanical properties

From the comparison of physical properties, it can be seen that the two mechanical properties are not much different, and PC/PBT can completely replace ABS.

4. The shrinkage rate is not much different from ABS

The measured value of PC/PBT shrinkage rate of the same part is 0.5, and the measured value of ABS shrinkage rate is 0.48. This means that manufacturers do not need to make major changes to the previous mold can use PC/PBT production