New trend of material selection for socket

Socket is an indispensable electrical device in our daily life, work and entertainment. It involves people's life and various fields of national economic construction, and its safety performance is related to the daily life of thousands of households and the order of industrial production. Once the safety performance of such products has problems, it will become the direct cause of fire and other injuries. According to the statistics of the fire department, in recent years, fires caused by electrical reasons have become the first of all kinds of fire accidents, and nearly 80% of residential fires in urban and rural areas are related to sockets or lines. Visible, the quality of the socket is directly related to the people's home safety.

Current Situation of Socket Industry

At present, the production situation of mobile socket products in China is: more general products, less high-grade products; more common products, less special products. Compared with developed countries, the overall production level of China's mobile socket products has a certain gap in terms of quality, appearance and versatility. According to incomplete statistics, the number of manufacturers producing mobile sockets and other electrical accessories in China has reached more than 1,000. In addition to the qualified products produced by regular large factories, the domestic market is also full of a large number of three-no products that do not meet the standards and have not passed the inspection. Especially in some secondary and tertiary markets, poor quality mobile socket products can be seen everywhere to occupy the market share at extremely low prices, the materials used in these markets are difficult to meet the standard requirements in terms of heat resistance and flame retardancy. The products are severely aged, and the insulation performance and strength are reduced accordingly. They are prone to leakage or deformation, and there are serious safety hazards.

current situation of material application

ABS is the traditional material currently used in the mobile socket industry. However, the oxygen index of ABS resin is only 18%, it is easy to burn in the air and produces a lot of smoke and toxic gases, and its smoke is the largest among all kinds of plastics. With the improvement of people's quality of life and the enhancement of safety and environmental protection awareness, ABS materials show more and more problems.

The author can be summarized in three points:

(1) Flame-retardant ABS will produce a great odor during the injection molding process, which seriously affects the health of production workers;

(2)ABS additional flame retardant properties after the price rose sharply, the lack of market competitiveness;

(3)ABS materials are naturally prone to yellowing, and produce smoke and toxic gases when burned, which is not environmentally friendly.

In view of the current application status of materials in the field of mobile sockets, it is urgent to develop new flame retardant materials to replace the most used ABS materials, which has met the multiple requirements of safety and environmental protection. The author's unit cooperates with Shanghai Rizhisheng, a well-known domestic material manufacturer, to jointly develop a new type of flame retardant polypropylene material.

Original intention of scheme design

Under the premise of ensuring the performance of the mobile socket shell material, improve the safety performance indicators, replace the current flame retardant ABS material with flame retardant polypropylene, reduce material costs and increase the market competitiveness of products.

Content of scheme design

a Security analysis

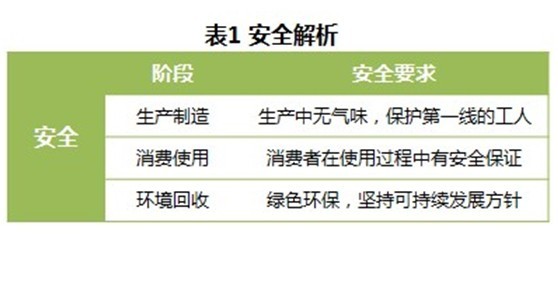

For the safety of household appliances, the average person stays on the concept of no leakage and no ignition. But for mobile socket manufacturers and material manufacturers, this understanding is far from enough. Here, the author of the mobile socket in the manufacturing, consumer use, recycling and other stages of the security issues that may arise, are analyzed, as a basis for the design of materials. The specific analysis is shown in Table 1:

B Safety indicators

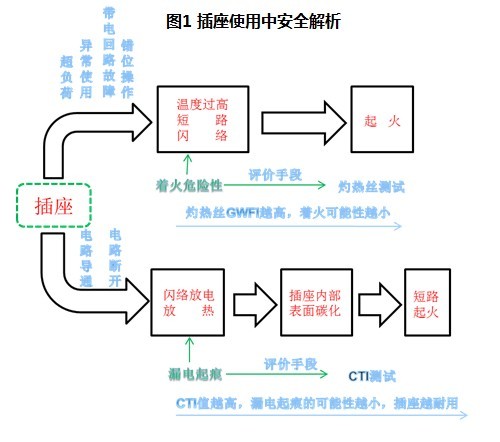

In the material design process, the selection of polypropylene substrate itself can be recycled, coupled with the selection of environmentally friendly flame retardant additives, can ensure that the material in the production process without unpleasant smell, in the material after the final scrap will not cause harm to the environment of human survival. The most important thing is whether the product can be guaranteed in the process of consumer use and whether it can protect electrical appliances. Relevant analysis is also carried out here, as shown in Figure 1:

There are two extremes in the use of the socket:

(1) socket overload abnormal use or dislocation operation, resulting in metal electrode temperature is too high or short circuit phenomenon, when the temperature reaches the ignition point of the plastic material used in the socket shell, it will cause the material to ignite, causing a fire.

(2) Due to the instantaneous flashover discharge of the circuit generated during the plug-in of the socket, the local high temperature causes the socket surface to carbonize, which will eventually lead to short circuit fire or invalid socket for a long time. In the former case, the ignition risk of the material can be judged by evaluating the glow wire temperature (GWFI) of the material. For the latter, the safety of the material is judged by evaluating the tracking resistance index (CTI).

Outlook

Safer, more environmentally friendly, and lighter will be an important goal for the future socket industry. The introduction of new materials is an important breakthrough. Her superiority in the mobile socket industry has been verified, and an epoch-making change is coming.