Maintenance and material selection of washing machine motor

Over the years, China's washing machine industry has maintained a rapid, sustained and efficient development trend, and the production scale of domestic washing machines continues to expand. At the same time, the central government's comprehensive promotion of home appliances to the countryside policy has also greatly promoted the further development of the washing machine industry. The application of a large number of new technologies and new devices has greatly improved the product performance of washing machines, and at the same time, the maintenance of washing machines has become increasingly complicated, which has brought more requirements to the technicians engaged in washing machine maintenance.

In the common maintenance items, mainly include:

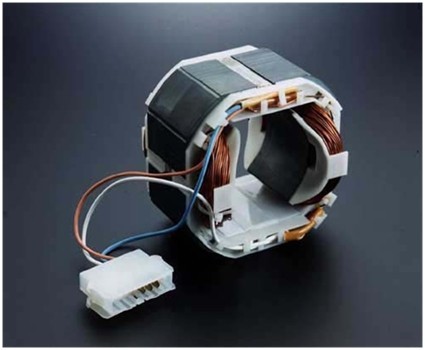

1. Replacement of washing machine motor;

2. Inlet valve maintenance and replacement;

3. Replacement of water level sensor;

4. Microcomputer control circuit board replacement;

Among them, the burning of the washing machine motor is the most common washing machine failure, especially in some campuses, commercial coin-operated washing machines, often the most such problems. Usually, the main reasons for the burning of the washing machine motor are:

1. Forced Stoppage

If the pulsator or agitator is stuck by clothes or foreign objects, and other reasons, the motor is forced to be energized but not turned, and the continuous starting current will eventually cause the winding to burn out.

2. Severe damp

Single long-term repair in humid environment, such as improper maintenance, or serious damp, or poor insulation treatment in the original manufacturing process, or long-term water overflow in the washing machine, will reduce the insulation performance of the motor, causing inter-turn winding short circuit, current increase, abnormal high temperature, resulting in winding burning.

3. Overweight load

When the laundry exceeds the rated amount of washing too much, it may also cause the motor to overload and the winding to overheat and burn.

Because the burning of the washing machine motor is not only the damage of a single motor, but even the burning of the washing machine, and people are using the washing process, the washing machine is usually in an unattended state. Therefore, at the beginning of 2009, the flame retardant requirements mentioned in the safety standard for unattended electrical appliances (IEC 60335) proposed by the European IEC organization-that is, unattended household appliances, the actual materials used must meet the requirements of the IEC organization for glow wire flame retardant: 750 degree glow wire flame retardant test burning time <2 seconds. Domestic and foreign enterprises engaged in the production of unattended electrical appliances, such as Siemens, Haier and Midea, require that the flame retardant reinforced engineering plastics used in their product components must meet this requirement.

In addition, in recent years, with the occurrence of fire incidents caused by unattended spontaneous combustion of electrical appliances, the safety maintenance of the electrical appliance industry has attracted people's attention, and people look forward to the voice of electrical safety services seems to be growing. In terms of safety services, the approach taken by dealers is to mark the life limit on electrical products and upgrade them in time to extend the after-sales service time.

However, in order to realize the long-term safety of household appliances, especially unattended electrical appliances, especially the long-term safety of key components, it is necessary to develop science and technology, that is, to develop the flame retardant and other properties of the materials used. The usual flame-retardant reinforced engineering plastics can only meet the V-O requirements mentioned in the US UL-94, and cannot meet the requirements of the Glow Wire flame-retardant test and the leakage trace index CTI ≥ 300V proposed by the IEC organization at the same time. At present, environment-friendly flame-retardant reinforced engineering plastics that can meet both UL-94 flame-retardant and glow-wire flame-retardant and high CTI values of IEC-organized unattended electrical appliances are scarce in the domestic and foreign markets. Therefore, the development of environment-friendly flame-retardant engineering plastics that can meet the long-term safety needs of IEC 60335 unattended electrical appliances has a broad market space.