Standard for Household and Similar Electrical Appliances-Requirements for Materials

The International Electrotechnical Commission (IEC) was established in 1906 and has a history of 109 years. It is the world's first international electrical standardization body, responsible for electrical engineering and electronic engineering in the field of international standardization. It ensures that its standards and conformity assessment programs are used as a global priority and to the greatest extent possible, evaluates and improves the quality of products and services involved in its standards, and has made great contributions to improving the effectiveness of the industrialization process and improving human health and safety.

IEC60335-1 the safety of household and similar electrical appliances, the safety of devices under normal use and abnormal use conditions is considered. It not only considers the danger of electricity, but also has a comprehensive assessment of the danger of machinery, fire and surrounding environment that the appliance may encounter. It recognizes the international general risk protection level, such as electric shock, machinery, heat, explosion, environment, fire and radiation, and the corresponding material to meet the corresponding requirements should meet the conditions.

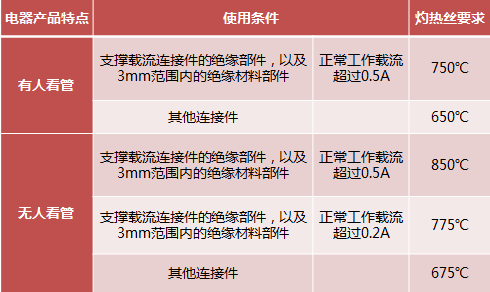

Understanding this standard is not only conducive to solving the following questions: why do the glow wire requirements of the same product have the difference between 750 ℃ and 850 ℃? While some components require 775 ℃, what factors are these requirements related to? Where does the test temperature come from? And it is conducive to the targeted development of corresponding materials and the development trend of corresponding component materials. The following authors combine the IEC603335-1/GB4706.1-2005 standard to explain the different requirements of this standard for materials.

Leakage current and electrical strength at operating temperature

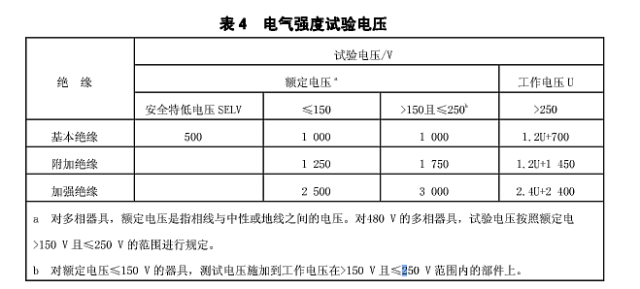

The material should have a certain electrical strength and withstand the impact of transient overvoltage, and there should be no flashover during the test. The applied voltage corresponding to the electrical strength is shown in the following table.

Non-normal operation

The structure of the workpiece should be able to eliminate the fire hazard caused by abnormal operation or misoperation, and mechanical damage that impairs safety or electric shock protection. This requires the material to have a certain degree of resistance to high temperature and thermal deformation during the locked-rotor test.

Mechanical strength

The appliance is rigidly supported and is capable of withstanding an impact energy test of 0.5J at every possible point of the housing. For easily accessible parts of solid insulation, there should be no material separation and be able to withstand the electrical strength test after the specified steel is scratched against the insulation surface with a force of 10N with the test nail.

Creepage distance, electrical clearance and solid insulation

The structure of the part should make the creepage distance, electrical clearance and solid insulation sufficient to withstand the electrical stress that the appliance may experience. At the same time, the electrical clearance corresponding to different material groups under the specified working voltage is different, which requires that the CTI of the material must be within a certain range when the electrical clearance is certain.

Heat and flame resistant

Exterior parts made of non-metallic materials, parts of insulating materials used to support live parts, and parts of thermoplastic materials used to provide additional insulation or reinforced insulation shall be sufficiently heat resistant. In general, the test temperature is: 75 ℃ 2 ℃ for external parts

Parts supporting live parts 125 ℃ 2 ℃

Non-metallic material parts shall be resistant to ignition and flame spread, and different glow wire requirements for unattended and attended conditions are specified in the standard.