Application Bottleneck and Solution of Flame Retardant Reinforced PET in Coil Skeleton

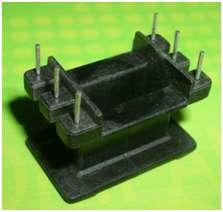

Coil skeleton is the most common component in electronic and electrical equipment. It is a kind of bracket used to wind coils and play a supporting role. The most common coil skeleton are transformer coil skeleton, inductance coil skeleton, solenoid valve coil skeleton and ignition coil skeleton.

At present, the common coil skeleton materials on the market include flame retardant PA, flame retardant reinforced PBT and flame retardant reinforced PET. With the increasingly fierce market competition, electronic product manufacturers continue to reduce costs and improve product performance to meet the needs of consumers. Under this trend, the advantages of flame retardant reinforced PET materials are highlighted: compared with modified nylon, the system cost of PET materials is only 2/3 that of nylon materials, while the water absorption rate is less than that of nylon, and the electrical properties far exceed PA materials; Compared with PBT, PET not only has the characteristics of PBT, but also has higher heat resistance and long-term service temperature, higher mechanical properties and lower cost than PBT products, more importantly, PET has better electrical properties than PBT, and is more suitable for coil skeleton materials with higher electrical performance requirements.

However, if PET is to be successfully applied to coil skeleton materials, many bottlenecks need to be solved:

(1) The coil skeleton material is required to have excellent apparent performance and short injection molding cycle.

Due to the lack of structure of the coil skeleton material itself and the process of injection molding, the surface of the coil skeleton will not be smooth or even have burrs, resulting in wire breakage due to hanging on the enameled wire during winding, thus affecting the quality of the coil product and the smoothness of production. At the same time, the manufacturers of coil skeletons are generally labor-intensive enterprises, and efficiency is the most critical factor for such enterprises to pursue profit maximization.

However, due to the rigid benzene ring on the main chain of PET, the flexibility of the molecular chain is poor and the mobility is weak. In the crystallization process, the transition from cis to trans, which is completed by crossing the extremely high "energy barrier", requires more energy, making its crystallization speed the slowest among all engineering plastics. It is precisely because of its slow crystallization speed that its injection molding cycle is much longer than that of ordinary engineering plastics, not only seriously affect the production efficiency of injection molding, but also easily produce appearance problems. In order to solve the problem of slow crystallization speed of PET, two aspects must be started. First, to reduce the "energy barrier" from cis to trans inversion, accelerators are needed to "smooth" the PET molecular chain to make it easier to complete cis to trans inversion. Secondly, the growth process of PET crystal nuclei is accelerated by the abnormal nucleation effect of nucleating agents, which helps them to complete the crystallization quickly in the whole process of PET crystallization.

cis

trans

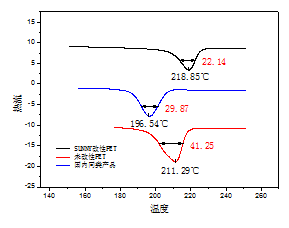

Under the same crystallization and melting conditions, the half-peak width of the thermal crystallization peak of the material in the DSC diagram reacts to the crystallization speed of the material, and the narrower the width value, the faster the crystallization speed of the material. From the figure, we can find that under the joint action of accelerator and nucleating agent, the half peak width of PET after crystallization modification is 22.14, only half of that of unmodified PET(41.25), which greatly shortens the molding cycle of the material, improves the injection efficiency and avoids appearance problems. Different from the above, the peak value of some domestic PET products is relatively low (196.54 ℃), which is more caused by the fracture or excessive plasticization of PET molecular chain. Although the crystallization rate of the material can be improved (the peak width is reduced), it greatly affects the mechanical properties of the material.

(2) The coil skeleton material is required to have a certain degree of toughness while having excellent strength.

When winding enameled wire, the coil skeleton basically adopts automatic or semi-automatic method. If the external tensile force of the coil exceeds the rigidity of the skeleton, the coil skeleton will be deformed or imperceptible micro-cracks, which may easily lead to electric shock and cause accidents when users use it. Even some coil skeletons with unique structures require that the injection molded coil skeleton be opened first, and then closed after winding.

Although PET has the strength that surpasses PBT and approximates PA, the conjugated system formed by ester group and benzene ring in PET chain segment structure increases the rigidity of molecular chain, resulting in poor impact resistance of PET. Therefore, in the application of coil skeleton, PET material must be endowed with certain toughness. However, PET is a very special polymer, regular the method of adding toughening agent can not effectively improve the toughness of PET, because the toughening agent will inhibit the crystallization of PET, resulting in imperfect crystallization of PET, and ultimately affect the toughness of the material. In contrast, the modified method of reactive extrusion is more effective. By compounding PET tackifier and toughener with reactive groups to prepare reactive impact modifier, the high impact resistance of PET material can be realized without affecting the perfection of PET crystallization, and its impact strength is about 30% higher than that of ordinary PET material, thus meeting the requirements of coil skeleton for material toughness. This method has been applied for a national patent (application number: 201310694395.5).

(3) the requirements of the coil skeleton material has excellent heat resistance

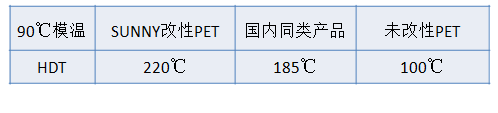

When the coil skeleton works under a large current, it will generate a lot of heat. Once the surrounding heat dissipation performance is insufficient, it is easy to accumulate high temperature, and the coil skeleton with poor temperature resistance will deform at high temperature, which will affect the electrical performance and even cause accidents. Propose safety hazards. When selecting the material of the coil frame, the thermal deformation temperature of the material under 1.82MPa is generally above 200 ℃.

As mentioned earlier, the molecular structure of PET not only makes its crystallization speed slow and crystallization time long, but also makes PET crystallization imperfect, which seriously affects the temperature resistance of PET materials. The heat distortion temperature (HDT) of 30% glass fiber reinforced flame retardant PET material without crystallization modification is only about 100 ℃ at room temperature. In order to obtain a well-crystallized, high-temperature-resistant PET material, usually the material supplier will require the injection molding factory mold temperature above 130 ℃. However, the application of the synergistic effect of accelerator and nucleating agent can effectively improve the crystallization perfection of PET while improving the crystallization rate of PET. It only needs to reach a thermal deformation temperature above 220 ℃ at a mold temperature of 90 ℃, which means that the injection molding factory does not need to add a mold temperature machine, and the injection molding can reach a thermal deformation temperature of nearly 200 ℃ at normal temperature, which can effectively reduce the cost of equipment and electricity.

To sum up, according to the material requirements of the coil skeleton, the flame retardant reinforced PET material developed by Shanghai Rizhisheng can not only meet the basic requirements of the coil skeleton material (such as UL94,1.6mm V0 grade), but also have extremely short injection molding cycle, high strength, excellent impact resistance and excellent heat resistance, which can fully meet the use requirements of the coil skeleton.

The flame-retardant reinforced PET material can be applied not only to the coil skeleton, but also to many components such as connectors, relay bases, timer housings, power plugs and electrical switches.