Nano flame retardant-a new choice of flame retardant materials

With the continuous development of science and technology and the continuous improvement of the quality of life, people put forward higher and higher requirements for flame retardant products, from simple flame retardant to low smoke, non-toxic to green environmental protection, recycling, combustible materials from the initial only consider flame retardant performance, to have excellent flame retardant performance, appearance and mechanical properties, etc, then pay attention to the harmful effects on the ecological environment and human health after processing, use and abandonment. At present, flame retardant materials have excellent flame retardant properties, which can block combustion and delay fire to a certain extent, but there are also deficiencies in mechanical properties and ecological environment. With the application of nanomaterials in the fields of mechanics, electromagnetics, thermology and optics, the development of nano-flame retardant technology is beneficial to improve the shortcomings of traditional flame retardant technology, and will have broad development prospects in the field of flame retardant materials in the future.

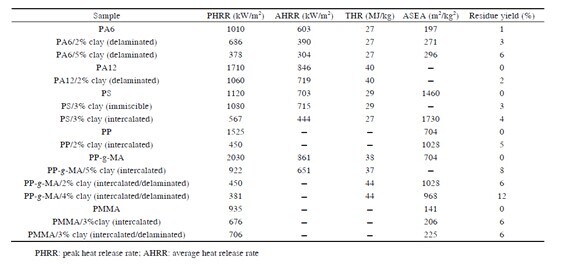

Gu Ming, a nano-flame retardant system, is a new type of flame retardant system. The addition of a very small amount (≤ 5% Wt) of nano-flame retardant can significantly reduce the heat release rate (HRR) and smoke density (SEA) of polymer materials during combustion, delay the combustion process, and improve the mechanical properties of materials to varying degrees. It is known as a new revolution in flame retardant technology.

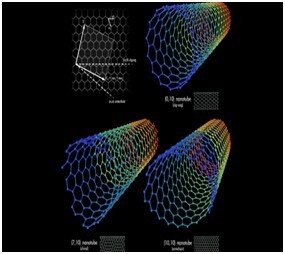

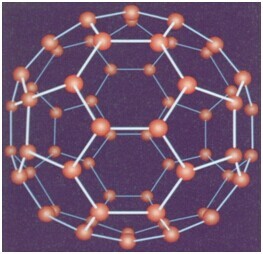

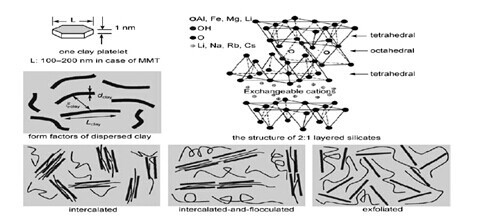

Nano flame retardants can be divided into the following three types according to dimensions: a. one-dimensional nano materials: carbon nanotubes (Carbon Nanotubes) and various whiskers, such as magnesium salt whiskers and calcium carbonate whiskers; B. two-dimensional nano materials: layered clay, such as montmorillonite (MMT), kaolin, graphite oxide, layered double oxide (LDH), etc.; C. zero-dimensional nano materials, nano silicon hydroxide, magnesium hydroxide, titanium dioxide and fullerene (C60).

carbon nanotube

Fullerene (C60)

Layered silicate nano-flame retardant system

Polymer/layered silicate nano-flame retardant materials involve cationic clay mineral montmorillonite, anionic clay mineral layered double hydroxide, non-ionic clay mineral kaolin and other raw materials, through the formation of intercalation or exfoliation structure, the preparation of PA, PP, PE and PMMA nano-composite flame retardant materials.

Structure of Montmorillonite and Polymer/Clay Nanocomposites

Nano-layered silicate contains carbonized layer, which can reduce the peak value of heat release rate (PHRR) in the combustion process, and the silica-like components formed by the decomposition of clay at high temperature migrate to the surface, enriching silicon and oxygen atoms on the surface, reducing the relative solubility of carbon atoms, forming a barrier layer, blocking the heat conduction between the polymer surface and the external heat source, thus delaying the combustion of the material and improving the flame retardant performance of the material, effectively reduce the production of smoke, toxic substances, etc. when the composite material is burned.

Combustion parameters of polymer/layered silicate nanocomposites

2. Carbon nanotube flame retardant system

Researchers found that PP/carbon nanotube (CNT) nanocomposites have the following obvious advantages compared with PP/layered nanosilicate composites: a. carbon nanotubes are easy to disperse and do not need organic treatment; B. no compatibilizer such as PP-g-MAH is required, and the peak heat release rate and mass loss rate of the material can be greatly reduced by adding only 0.5 percent of carbon nanotubes; c. The addition of organoclay reduces the ignition time of the system, while the ignition time of the carbon nanotube system remains basically unchanged.

3. Fullerene (C60) flame retardant system

Fullerene (C60) has an ultra-high ability to capture free radicals and is called a "free radical sponge". One C60 molecule can capture at least 34 free radicals. The degradation and combustion of polyolefin are generally carried out by β-scission of free radical chain. It can be imagined that C60 will have a great influence on the combustion degradation performance of PP. C60 can greatly improve the thermal stability of PP, increase the thermal oxidative degradation temperature of PP, delay the ignition time of PP and reduce the peak heat release rate of PP combustion when adding C60. This is because on the one hand, C60 absorbs the free radicals generated during PP combustion, which affects the normal combustion of PP. On the other hand, each C60 molecule can react with dozens of free radicals to increase the viscosity of the melt. As a result, it delays the combustion of PP and reduces the peak heat release rate during combustion.

4. Problems Existing in Nano Flame Retardant System

a. At present, the organic intercalation agent of clay is still dominated by flammable long-chain alkyl salts, and there is a lack of organic intercalation agent for improving flame retardant performance. The salt is easy to degrade at high temperature and reduces the ignition time of the material, so it is not suitable for engineering plastics with high processing temperature.

B. The mechanism of nano-flame retardant still lies in the general explanation such as the blocking layer mechanism of clay system, the free radical capture mechanism and the network structure of carbon nanotube system, and there is no systematic research and elaboration.

c. Although the nano-flame retardant test has a significant effect on reducing the peak heat release rate and mass loss rate of the material, it is not satisfactory in the traditional UL-94 and LOI tests. The relevance of different flame retardant mechanisms and combustion test methods needs further study. It is an important development direction of flame retardant system in the future to combine nano flame retardant with traditional flame retardant.

In summary, nano-flame-retardant composite materials have good flame-retardant properties, good environmental protection effects, less toxic gases emitted during combustion, less nano-filling, and products tend to be multifunctional. In the future, they will be used in automobiles and electronics. There is a lot of room for development in the fields of electrical appliances and aviation. Although there are still many practical problems that need to be solved urgently, with the continuous progress of engineering technology, nano flame retardant materials will have long-term progress.