Application of Plant Fiber Reinforced Materials

Natural fiber is one of the most abundant natural polymer materials in nature. The total amount of cellulose grown in nature is as much as 100 billion tons per year, far exceeding the total reserves of existing oil on the earth. Not only huge reserves, plant fiber composite materials and its unique advantages. As can be seen from the comparison in the table below, although the tensile strength of plant fiber is less than that of glass fiber, its specific strength and specific modulus are close to that of glass fiber, and its density is only 60% of that of glass fiber, which means that the density of plant fiber composite material is smaller under the same content, and its price is lower.

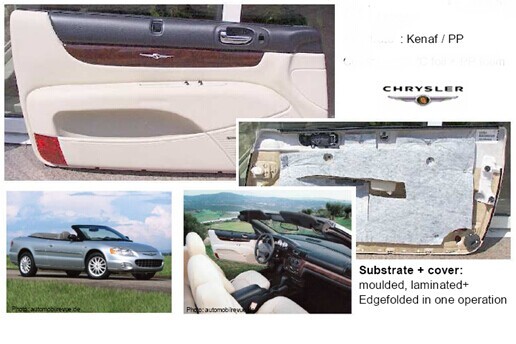

Plant fiber composite materials also have good thermal and sound barrier properties, and are suitable for environments that require sound insulation and heat insulation. Some foreign automobile enterprises have long used plant fiber reinforced materials in their cars and applied for relevant patents. For example, Germany's R S Technology Company uses PP and hemp fiber to mix and prepare parts such as door panels or storage boxes for high-end cars.

Early plant fiber composite materials, due to the easy degradation of plant fiber and high viscosity processing injection molding, mostly die-casting molding. With the development of technology and the gradual solution of degradation problems, plant fiber reinforced composites that can be injection molded have also been reported.

Since plant fibers are easily degraded at high temperatures, the matrix resins used for plant fiber reinforcement are mainly concentrated in PVC,PE,PP and other resins with lower processing temperatures. For plant fiber reinforced nylon materials, the preparation is relatively difficult, which limits its application in structural components. Related studies have shown that the degradation of plant fibers is mainly due to the low temperature tolerance of non-cellulose components in the molecular structure. Therefore, the key to the preparation of plant fiber reinforced nylon materials is to reduce the non-cellulose components in the plant fiber and to reduce the processing temperature of engineering plastics such as nylon. I believe that with the development of technology, plant fiber reinforced nylon materials will get greater development.