The influence of RoHS directive on the development of flame retardant plastics

In 2003, the European Union issued two directives, RoHS and WEEE. The RoHS directive is about restricting and prohibiting the use of certain toxic and hazardous substances and elements in electrical and electronic equipment, and the WEEE directive is about recycling waste electrical and electronic equipment. Directive. These two directives were transformed into the laws (regulations) of the 15 EU member states in 2004.

The RoHS directive was formulated by relevant experts from EU countries after decades of in-depth discussion. Its purpose is to minimize the impact of electronic and electrical products on the environment, and requires product manufacturers to consider more ecological environment in product design, use and recycling. And consumer safety factors, and promise more responsibilities to achieve sustainable development that saves resources and protects the environment. The directive stipulates that from July 1, 2006, new electronic and electrical products listed on the EU market should restrict and prohibit the use (reduction and substitution) of the following six toxic and harmful substances and elements: lead, mercury, hexavalent chromium, cadmium, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE).

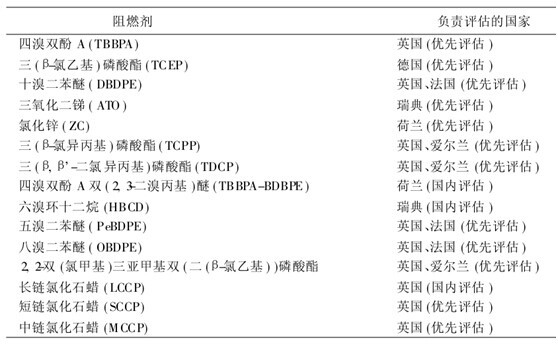

Table 1 Hazard assessment of halogen-containing flame retardants in the EU

After the promulgation of the RoHS directive, flame retardants and flame retardant plastics around the world (especially in Western Europe) are in a comprehensive structural adjustment stage to make them meet both flame retardant and environmental protection requirements. Including speeding up the process of halogen-free flame retardant plastics, the development of new flame retardant standards. Western Europe has proposed to implement new flame retardant classification methods and testing standards for building materials and other industries. China has also submitted and approved national standards for the combustion performance grade of building materials and products. This standard has common characteristics with the above-mentioned new Western European standards, that is, in evaluating the flame retardant performance of materials, it emphasizes heat release rate, fire development rate, smoke generation, corrosion and toxicity of combustion products, etc. In order to meet the requirements of such new standards, traditional halogen-based flame-retardant materials will be unable to match, and the market will gradually shift to the use of carbon-based flame-retardant plastics (especially intumescent flame-retardant plastics) and thermosetting flame-retardant plastics, which is also in line with the RoHS directive on the restrictions and prohibition of the use of harmful substances.

In China, one of the largest users of flame-retardant plastics, especially flame-retardant engineering plastics, is the electronic and electrical industry. In 2006, China promulgated China's electronic information product pollution control management measures, prohibiting and restricting the six toxic and hazardous substances and elements proposed in the RoHS directive for electronic information products produced, sold and imported in China, so as to realize the substitution and reduction of toxic and hazardous substances in China's electronic information products, enhance the international competitiveness of the electronic information industry. In response to the above changes, China's halogen-free flame retardant plastics to flourish, including halogen-free flame retardant polyester, polyamide, polycarbonate and other engineering plastics and halogen-free flame retardant polyolefin, ABS and other general plastics are gradually developed. With the efforts and cooperation of related industries, the halogen-free process of Chinese plastics is expected to reach the level of Western Europe and the United States in the future.