Smoke density method-determination of the smoke-generating properties of plastics from combustion

The vast majority of plastics are flammable and flammable materials. In the presence of fire sources, these materials are easy to cause and spread fire. When burning, the calorific value of the plastic is high, and the propagation rate is extremely fast, and it is not easy to extinguish. A large amount of smoke is produced, and the smoke is the primary risk factor for death in a fire. Therefore, in addition to flame suppression, combustion smoke suppression has become a secondary requirement for flame retardant plastics. NBS box smoke method is the basic method to determine the smoke generation of plastic combustion. This experimental method is to apply Bouguer's law to the attenuation of the speed of light after passing through the smoke box to evaluate the smoke generation, that is, under the condition that the geometric size of the smoke box and the exposed area of the sample are fixed, the degree of light attenuation after the test beam passes through the smoke box to evaluate the smoke generation of the material when burning.

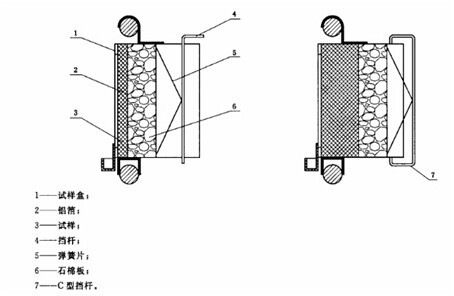

The picture shows the smoke density testing machine

Test standard

Test method for specific optical density of smoke produced by solid materials GB/T10671-2008, ASTM E662.

GB8323-2008 of Test Method for Flammability of Plastics-Smoke Density Method

Metrics Definition

1. specific optical density: in the test chamber of a certain container, in the over-weighing of smoke generated by the combustion of the sample, the degree of light attenuation after passing through the smoke layer is measured, and the corresponding optical density is derived, which is a measure of smoke generated by the combustion of materials.

2. Smoke density: that is, the maximum specific optical density, is an indicator for evaluating the smoke of the material.

experimental method

1. Purification and cleaning test chamber

2. Preparation of the sample, measure the length, width and thickness of the sample, cover the back of the sample with a complete aluminum foil of about 0.04mm, and wrap it around the edge of the sample to the periphery of the test surface, and put it into the sample box. A 75mm × 75mm × 10mm asbestos board is used as the backing, and the sample and the backing are fixed in the sample box with a spring sheet and a fixing rod. If the thickness of the sample is greater than 15mm, the C- type fixing rod can be used for fixing. Cut off the excess aluminum foil exposed on the test surface, and bend the aluminum foil at the notch forward to guide the molten material of the sample into the sample box.

The picture shows the sample preparation method

3. The burner shall be removed during flameless combustion. When flame combustion is carried out, the burner is installed on the burner in the test chamber so that the center line of the two horizontal combustion is 6.4±1.5mm from the lower edge of the sample box opening, and the port of the tube is 6.4±0.8mm from the sample surface.

4. Turn on the power supply and adjust the current of the radiation furnace. Close the smoke exhaust port and the test chamber door, and open the air inlet.

5. When the radiation intensity is stable to the specified value, block the parallel beam with the movable shutter, adjust the zero point of the amplifier, and indicate that the transmittance is 0; Remove the shutter and adjust the gain of the amplifier to indicate that the transmittance is 100.

6. During the flame combustion test, adjust the propane flow rate to 1250 px3/min and the air flow rate to 12500 px3/min, and ignite.

7. Replace the blank sample box on the bracket with the sample box with the sample box installed, quickly close the door of the test box and start the recorder. When the recorder pointer is closed, immediately close the air inlet.

8. Record the relationship curve between transmittance and time, and obtain the minimum transmittance value Tm within 20min.

9. Immediately replace the test sample box with a blank sample box and quickly remove the smoke in the test box. If the flame combustion test is carried out, the gas source must be turned off first to extinguish the flame of the burner. Smoke is discharged until the maximum transmittance value Tc is obtained.

Result evaluation method

The smoke density (maximum specific optical density) can be calculated from the minimum transmittance value Tm and the maximum transmittance value Tc. Generally, the smoke density of plastics is less than 300. The smoke density of POM, PP, LDPE and PA6 is less than 300, which can be regarded as smokeless materials, while resins with smoke density> 300 such as PET, PC and PS need smoke elimination treatment.