Application of Engineering Plastics in Low Voltage Apparatus

Low-voltage electrical appliances refer to electrical appliances that function as on-off, protection, control or regulation in circuits where the AC voltage is less than 1200V and the DC voltage is less than 1500V. Its main applications include miniature circuit breakers and leakage protection switches, AC contactors, molded case circuit breakers, etc.

Industry background

The two EU electrical product directives (including low-voltage electrical)-the WEEE directive and the ROHS directive.

From 1 July 2006, electrical and electronic products that use or contain heavy metals (lead, mercury, chromium) and flame retardants such as PBDEs and PBBs will not be allowed to enter the EU market. At the same time, there are more than 30 kinds of substances of high concern in the REACH regulation, and the implementation of the major EU member states is also strengthening, which increases the threshold for electrical products to enter the EU market, and needs to improve the environmental protection function of electrical products. low-voltage electrical appliance manufacturers need to assume greater environmental responsibility. In the field of low-voltage electrical appliances, thermoplastic engineering plastics will be more widely used instead of thermosetting plastics.

Due to the good recycling capacity of thermoplastic materials, 30% to 100 of recycled materials can be used while maintaining certain mechanical strength and flame retardancy. Compared with compression molding, the cycle is shortened, time-consuming trimming and oven drying are not required, and the injection molding productivity can be improved by increasing the number of mold cavities. Save the recycling cost of thermosetting materials. Due to low density, the weight of parts is reduced by nearly 30%, the design freedom of complex parts that cannot be handled by compression molding is improved, and post-processing operations are saved.

Selection of thermoplastic engineering plastics

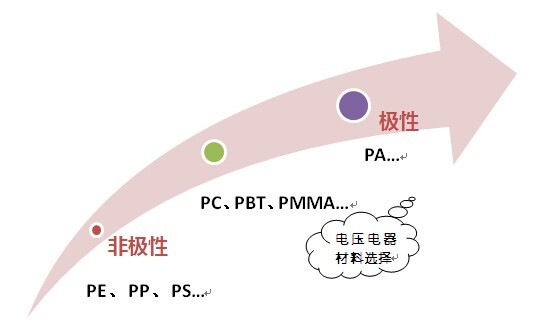

Applied to electrical products, mainly based on plastic insulation. In terms of electrical properties, plastics can be roughly divided into three categories: the first category is non-polar or low-polarity plastics, such as most of the olefin plastics in general plastics, such as PE, PP, PS, etc. These materials have low dielectric constant and dielectric loss, high resistivity, and are not affected by external frequency, temperature and humidity. The second category is polar materials, such as nylon, plasticizer PVC and phenolic molding compounds. Their dielectric strength and dielectric loss are much greater than those of the first type, and their resistivity is also lower. The third type of material is between one and two types, the dielectric constant is between 3 and 5, the tan δ is between 10-3 and 10-2, and the resistance is between 1014 and 1016Ω. Such materials include organic glass (polymethyl methacrylate), polycarbonate, PBT, polyimide, etc.

It is worth noting that the second and third types of plastics are greatly affected by external frequency, temperature and humidity. However, for low-voltage electrical appliances with plastic, the general plastic can be competent for low-voltage electrical appliances on the material insulation requirements. In contrast, its mechanical properties, thermal properties, flame retardant properties, processing performance, environmental protection, cost performance and service life are more important. Although PC, PA and PBT belong to the second and third types of materials, due to their excellent mechanical properties, thermal properties and processing properties, they are the first choice of plastic materials in the field of low-voltage electrical appliances.

The most common PA varieties are PA6 and PA66,PA6 has excellent comprehensive properties: good toughness, good performance stability; oil resistance, organic solvent resistance, chemical resistance; processing performance, excellent apparent performance. But PA6 also has shortcomings. Due to its low melting point, its temperature resistance is limited. Secondly, the water absorption is large, which leads to the dimensional change of the material, and the material becomes soft, which also reduces the insulation performance of the material, and the surface resistivity drops from 1014 ΩNaN to 1012~1013 ΩNaN. Compared with PA6 products, PA66 has higher mechanical strength, thermal deformation temperature has been greatly improved, which provides convenience for product design and relaxes the use environment. The material is not only used in small circuit breakers, leakage protectors and contactors, but also in micro switches, coil frames and other products.

PBT is an engineering plastic used in electronic and electrical products, which is second only to nylon. They not only have good dimensional stability, temperature resistance, excellent electrical insulation, weather resistance and other characteristics, but also have moisture and heat resistance, low warpage, easy molding and other characteristics. These products are mainly used for contactor base, coil frame, fuse box, electronic connector, small circuit breaker and leakage protection switch internal parts, and can meet the needs of different colors.

Modification mode

Pure materials can not meet the requirements of low-voltage electrical appliances for many properties of materials, and need to be modified to achieve.

Modification of mechanical and thermal properties

Plastic parts for low-voltage electrical appliances have certain requirements for mechanical properties and heat resistance. Unmodified PA and PBT cannot meet the requirements of mechanical strength. PA and PBT are crystalline materials. By adding minerals and glass fiber modification and reinforcement, its mechanical properties and heat resistance can be significantly improved.

Modification of Flame Retardant Performance

The modified plastic materials used in AC contactor products all require that the materials must meet the UL-94 1.6 mmV-0, environmental protection, EU RoHS and REACH standards, glow wire ignition temperature (GWT) of 960 ℃, and good electrical insulation performance.

Flame retardant modification is generally achieved by adding flame retardants, and halogen flame retardants have high flame retardant efficiency and economical price. At present, the main commonly used brominated flame retardants, mainly decabromodiphenyl ethane, brominated styrene, brominated epoxy, etc., it should be pointed out that although these flame retardants are halogen, but are in line with ROHS, REACH regulatory requirements, is an environmentally friendly material. On the other hand, halogen-free flame retardants are also maturing, mainly phosphorus, nitrogen, inorganic minerals or their compounds. At present, foreign halogen-free flame retardant effect is good, but the price is expensive, domestic flame retardants mainly exist temperature instability problem, in some applications are limited, but with more stringent environmental regulations and halogen-free flame retardant technology development, halogen-free flame retardant materials used in low-voltage electrical appliances will be the trend.

References:

http://www.doc88.com/p-161101400591.html

http://www.ahycdq.cn/display.asp?id=754