Application of Nylon in Low Voltage Electrical Apparatus

General requirements for plastic materials for 1. low-voltage electrical appliances

Plastic is used in electrical products, mainly based on its insulation. In terms of electrical properties, plastics can be roughly divided into three categories: the first category is non-polar or slightly polar plastics, such as most of the olefin plastics in general plastics, such as PE, PP, PS, etc. These materials have low dielectric constant and dielectric loss, high resistivity, and are not affected by external frequency, temperature and humidity. The second category is polar materials, such as PVC with plasticizers, phenolic molding compounds, and nylon. Their dielectric strength and dielectric loss are much greater than those of the first type, and their resistivity is also lower. The third type of material is between the 1. two types, the dielectric constant is between 3 and 5, the tan δ is between 10-3 and 10-2, and the resistivity is between 1014 and 1016Ω. Such materials include organic glass (polymethyl methacrylate), polycarbonate PBT, polyimide, etc. It is worth noting that the second and third types of plastics are greatly affected by external frequency, temperature and humidity.

However, for low-voltage electrical appliances with plastics, electrical insulation is often not very important, because there are few problems caused by insulation, and general plastics can be competent for the insulation requirements of low-voltage electrical appliances. In contrast, other properties are more important. These properties include: mechanical properties, thermal properties, flame retardant properties, processing properties, environmental protection, cost performance and service life.

Although polycarbonate, nylon and PBT belong to the second and third categories of materials, they are selected as the preferred materials by low-voltage electrical appliance manufacturers due to their excellent mechanical properties, thermal properties and processing properties. However, pure materials can not meet the requirements of low-voltage electrical appliances for many properties of materials, so they need to be modified to achieve.

Modification Methods and Effects of 2. Engineering Plastics

1. Improvement of mechanical and thermal properties

Nylon (PA) and PBT are crystalline materials, and the addition of minerals or glass fibers can greatly improve the mechanical and thermal properties of the material. Especially the glass fiber reinforced effect is the most obvious.

2. Improvement of flame retardant performance

Electrical products have penetrated into various fields, whether it is industrial manufacturing, transportation, national defense, or home appliances, communications, etc. everywhere. Since plastic is a combustible substance, in the event of a fire, the plastic plays a role in supporting combustion. According to statistics, fires caused by electrical aging or electrical accidents account for more than half of the total number of fires. Therefore, for safety reasons, plastic products for electronic appliances are required to be flame-retardant. Traditional flame retardants are considered to be environmentally unfriendly and prone to carcinogens such as dioxins. The European Union has banned the use of certain harmful substances in electronic and electrical products. Therefore, environmentally friendly flame retardants are used in electronic and electrical plastics.

(1) Halogen-friendly flame retardant system

The largest amount of halogenated flame retardants used in plastics is decabromodiphenyl ether. Although the European Union has listed it as an exemption list in the prohibited hazardous substances, there is a potential risk in choosing decabromodiphenyl ether because the related by-products are difficult to eliminate when producing this flame retardant. At present, the available halogen-based environmentally friendly flame retardants include decabromodiphenyl ethane, brominated polystyrene, brominated epoxy, BC-58 (phenoxy tetrabromobisphenol A carbonate oligomer), etc.

(2) Halogen-free and environmentally friendly flame retardant system

With the promulgation and implementation of the EU RoHS directive, halogen-free flame retardant is the general trend. At present, there are three types of mature halogen-free flame retardants: first, phosphorus flame retardants, second, nitrogen flame retardants, and third, hydroxide flame retardants, phosphorus flame retardants and nitrogen flame retardants can be used in PC, nylon and PBT. In recent years, silicon flame retardants and aromatic sulfonate flame retardants have also been developed, and these flame retardants have been used in PC to achieve good results.

Performance and use of special materials for 3. electrical appliances

1.PA6 special material for electrical appliances

Nylon 6(PA6) is formed by caprolactam ring-opening polycondensation, polyamide macromolecular structure contains a large number of amide groups, macromolecular terminal amino (-NH2) or carboxyl (-COOH), is a strong polarity, can form hydrogen bonds and has a certain reactivity of the semi-crystalline polymer. Because there are a large number of amide bonds, and amide bonds can be coordinated with water molecules to form hydrogen bonds, so it shows a certain degree of water absorption.

PA6 has excellent comprehensive properties: high strength, good toughness (wet state); oil resistance, organic solvent resistance, chemical resistance performance is good; friction coefficient is small, self-lubricating performance is excellent; processing performance is good. With the development of electronic appliances and communication equipment towards miniaturization, lightweight and high performance, the amount of nylon modified materials is increasing.

However, nylon materials also have shortcomings. First of all, the flame retardant performance is not good, and the non-modified nylon material cannot meet the flame retardant performance requirements of the electrical industry. Secondly, the water absorption is large, which leads to the dimensional change of the material, and the material becomes soft, which also reduces the insulation performance of the material, and the surface resistivity drops from 1014 Ω · cm to 1012~1013 Ω · cm.

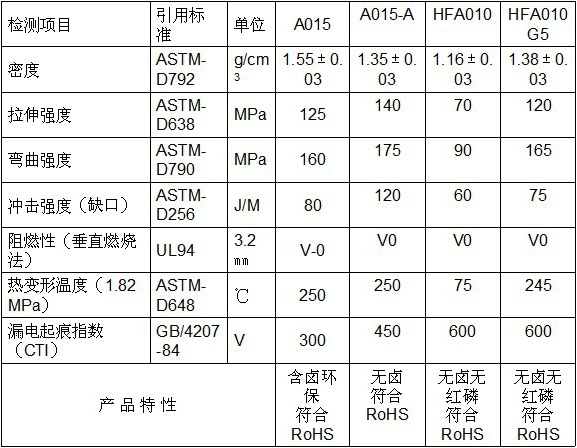

Risheng company for market demand, developed a series of nylon 6 flame retardant products, the main performance indicators such as table.

This series of products are mainly used for small circuit breaker and leakage protector shell and coil winding bracket and so on.

2.PA66 special material for electrical appliances

At present, electronic and electrical products are developing in the direction of miniaturization and multi-function, so the engineering plastics used are required not only to be flame retardant, environmentally friendly, but also to withstand higher ambient temperatures. Due to the limitation of the melting point of PA6 itself, the heat resistance of the modified product can not meet the requirements in some fields. For this reason, we have developed a flame retardant reinforced material for electrical appliances based on PA66.

Risheng series nylon 66 flame retardant product performance indicators are as follows.

This series of products are mainly used in electronic appliances, switch sockets, circuit breakers, small household appliances internal parts, connectors, electrical connectors, etc.

3. Application of high temperature nylon in electronic and electrical industry

Nylon has great potential in the electrical and electronics industry, and the demand for nylon for low-voltage switches has increased greatly. In small parts of electrical appliances, dense pins require plastic materials with high leakage resistance (CTI). At the same time, due to the trend of miniaturization of electrical equipment or the increase in operating current, the temperature of its internal components may rise considerably. The continued trend towards miniaturization of integrated circuit boards and the widespread adoption of surface mount technology (SMT) have led to smaller, thinner-walled surface mount components (SMDs). These electronic components need to withstand the high peak temperatures found in modern reflow soldering processes. This requires the use of materials with high long-term use temperature, high hardness and low creep properties at high temperatures.

Due to the excellent inherent characteristics of high temperature nylon (HTN), it not only has a heat distortion temperature of more than 265 ℃, but also has excellent toughness and excellent fluidity, so it can meet the temperature resistance requirements of SMT process for components. Plastic parts made with HTN high flow specifications can maintain dimensional consistency during reflow soldering processes up to 270°C. Such plastic parts often use materials such as LCP. But in terms of cost performance, HTN is good enough to compete with PPS, PEI, PES and LCP materials. Therefore, HTN can be applied to the following fields and markets: circuit breakers, connectors such as: power connectors, memory card connectors, sockets; motor components; computers and their auxiliary equipment; electrical products and household appliances.