New Direction of Flame Retardant Technology-Microencapsulation Technology

One. Microencapsulation Flame Retardant Technology

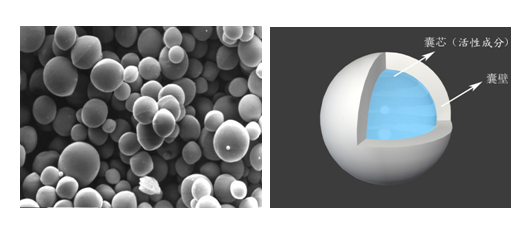

The microcapsule technology is a technology for forming fine particles by coating a dispersed liquid, solid or gaseous material with a polymer material. This technology protects the capsule core through the isolation of the capsule wall; and under certain conditions, the capsule wall will be destroyed and the active ingredients of the capsule core will be released.

Figure 1. Microcapsule particles

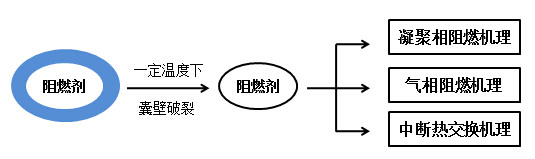

The microencapsulated flame retardant technology uses this special capsule wall coating structure to protect the flame retardant from external light, heat, humidity and other environmental factors. At the same time, the existence of the capsule wall also makes the microcapsule flame retardant able to withstand higher processing temperatures and pressures. When the part meets fire and produces high temperature, the bag wall melts and ruptures to release the flame retardant to achieve the purpose of flame retardant, the mechanism is shown in Figure 2.

Figure 2. Mechanism of microencapsulated flame retardant technology

II. Advantages of Microencapsulation Flame Retardant Technology

As we all know, microcapsule technology has a very wide range of applications in medicine, food, coatings and other industries. What are its unique advantages in the flame retardant industry?

At present, the widely used flame retardants are divided into inorganic flame retardants and organic flame retardants. These flame retardant materials often have problems such as water absorption failure, toxicity, high corrosion, poor stability or poor compatibility with the matrix, which will affect the long-term flame retardant performance of the parts. The flame retardant microencapsulation treatment can play a significant role in the following aspects:

The gaseous and liquid flame retardants treated by microencapsulation can be transformed into solid flame retardants, which is beneficial to processing.

2. For different matrix materials, the selection of appropriate wall materials is helpful to the dispersion of flame retardants and reduce the loss of mechanical properties of modified materials.

3. After microcapsule treatment, the volatilization and migration of liquid flame retardant components decreased significantly, and the flame retardant efficiency was higher.

4. The release of toxic components or irritating gases in the flame retardant can be avoided during processing.

5. The choice of shell material gives the flame retardant new physical properties, such as color, specific gravity, volume, etc.

Three. Selection of wall materials for flame retardant microcapsules

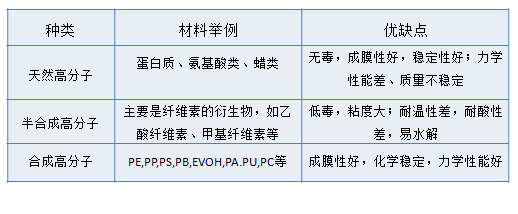

From the characteristics of flame retardant microcapsules, we can find that the existence of the capsule wall has a great influence on the physical properties of the flame retardant, so we should not only pay attention to the flame retardant components of the capsule core, but also select the shell components. The selection principles are as follows:(1) non-toxic and non-irritating;(2) incompatible with flame retardant;(3) good compatibility with resin matrix; (4) good film-forming;(5) melting temperature is higher than flame retardant processing temperature. In addition, the influence of special working environment should also be taken into account. For example, when flame retardant parts are structural parts, the selected bag wall material must have certain mechanical properties. Combustion-supporting materials cannot be used for parts with higher flame retardant grade. The shell polymer materials currently used are divided into the following three categories:

Table 1 Shell materials of flame retardant microcapsules

IV. Typical Application of Microcapsule Flame Retardant Technology

Microencapsulation technology can be applied to most of the flame retardants, and the research on microencapsulation of red phosphorus flame retardant is the most active.

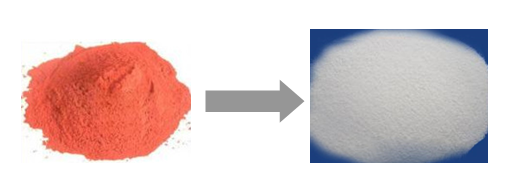

Figure 3. Red phosphorus whitening treatment

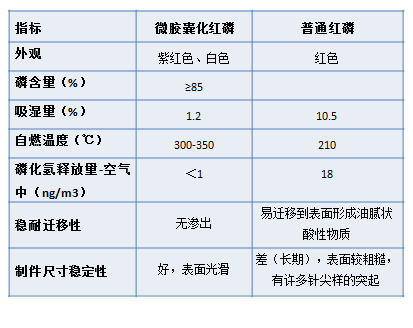

Red phosphorus is an efficient, non-toxic and environmentally friendly flame retardant. However, there are still two problems to be solved in the use process:(1) red phosphorus itself is an inorganic component and has poor compatibility with polymer materials, which is easy to form agglomeration in the matrix and seriously affects the mechanical properties of the material;(2) red phosphorus itself has color, which limits the parts to a few colors such as red and black. The microcapsule technology provides a good solution to the above problems, and as shown in Figure 3, the whitening treatment of red phosphorus can be achieved through the optimization of the capsule wall material and the coating process. In addition, microencapsulated red phosphorus has better heat-resistant temperature, lower water absorption and phosphine emissions. Table 2 is a comparison of the characteristics of microencapsulated red phosphorus and ordinary red phosphorus.

Table 2 Comparison of physical properties of microencapsulated red phosphorus and common red phosphorus

Five. Summary

In recent years, the research of microcapsule flame retardant technology in China has been developed rapidly, and related products have also appeared. However, the quality of the product still needs to be further improved. Future work should be devoted to the following aspects:(1) development and application of different flame retardant substrates and corresponding capsule wall materials;(2) full development of the synergistic flame retardant effect of capsule core and capsule wall;(3) improvement of coating technology;(4) development of nano microcapsule flame retardant materials, so as to improve the physical and chemical properties of flame retardant materials.