Common Misunderstandings of UL Flame Retardant Standard

UL flame retardant standard is a popular standard for daily inspection of whether materials are flame retardant or not. However, because it is an American standard, after translation, Chinese people have a variety of understanding of the standard. Each factory has its own set of "V0" grade, which brings great inconvenience to upstream and downstream manufacturers. The following is an analysis from several common flame retardant misunderstandings:

Myth 1: From the fire self-extinguishing to reach V0 level

This is the understanding of some small injection molding factories. There is only one standard for them to judge whether the material is flame retardant: self-extinguishing from the fire, that is, "the material cannot be ignited". Once it is burned, they will rate it as "not flame retardant enough"; The reason for this misunderstanding is that they do not understand the standard at all, only the hearsay cannot ignite in 10 seconds, and no matter how you explain it, only recognize your own standard;

Misunderstanding 2: HB grade is not flame retardant grade. Any material without flame retardant treatment can be marked with HB, which is also wrong.

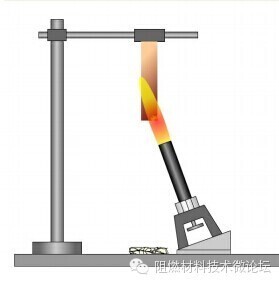

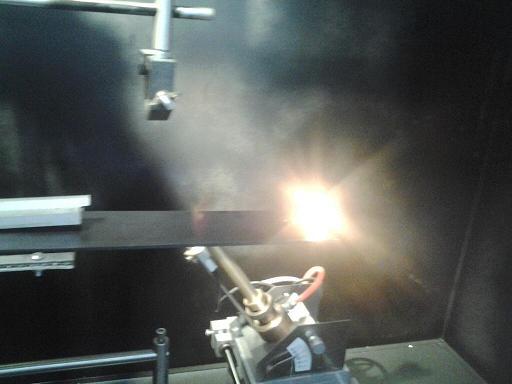

The actual HB grade is the lowest flame retardant grade in UL94 standard, usually called "slow burning grade". The test method is horizontal combustion determination method, which requires the combustion speed to be less than 40mm per minute for samples 3 to 13mm thick. For samples less than 3mm thick, the combustion speed is less than 75mm per minute; Or extinguish before the 100mm mark. In order to make HB grade, some color masterbatch manufacturers added flame retardants to the natural ABS(HB grade) after adding color masterbatch to achieve HB grade;

Misunderstanding three: flame retardant grade the higher the better, such as V0 must be better than V2

Different uses have different requirements for flame retardancy. Generally speaking, people always hope that the flame retardancy level of the material is higher. But in fact, all kinds of flame retardant test methods have their limitations, and their conclusions are relative. Therefore, the higher the flame retardant level, the better. For example, UL94 V-0 grade materials are generally considered to be better than V-2 grades. However, some electrical products require materials with resistance to arc ignition, then the V-2 grade is better than the V-0 grade. Because UL94 V-2 grade plastics do not form conductivity and coking under electrical action, which greatly reduces the possibility of fire, while UL94 V-0 grade plastics are the opposite.

Misunderstanding 4: UL yellow card certification is only V0, and products given to customers can be declared V0 no matter what color they are made.

This is the UL standard interpretation is not detailed and lead. Although it is possible that natural color materials can reach V0 grade and other color products can reach V0 grade, this is only possible, not all. Different materials, different flame retardant systems, and different degrees of color influence. For example, iron red has a considerable influence on flame retardant. Once, when a modification company was doing UL yellow card full series certification, natural color, white and black all passed V0 grade, but only stuck on red, the reason for the investigation turned out to be iron red, but it was OK to switch to organic dye;

Misunderstanding 5: In order to better promote their products, some flame retardant manufacturers generally do some experiments and give the recommended addition amount. For example, 18% of a flame retardant needs to be added to PBT to reach V0 level.

However, the customer cannot achieve this flame retardant effect according to this test during the trial. This is also caused by insufficient interpretation of the standard. The UL94 rating should be reported together with the thickness value, and it is not sufficient to report the UL94 rating without the thickness. General flame retardant manufacturers in order to reflect the high efficiency, usually only do the minimum amount of addition, in some thick products (usually 3.2mm) in the effect, and customers will be in order to better versatility, usually do thin products (1.6mm mostly) flame retardant, so the difference between the two sides is obvious.